Service

The OLFRY flip catalogue

Browse directly through our current complete catalogue online.

Download catalogues

The current OLFRY catalogue

The new OLFRY clinker strip catalogue

The magazine “The Clinker Brick”

Order catalogue

Please send me a printed copy of the following catalogues:

Downloads

Info for building owners

Info for architects

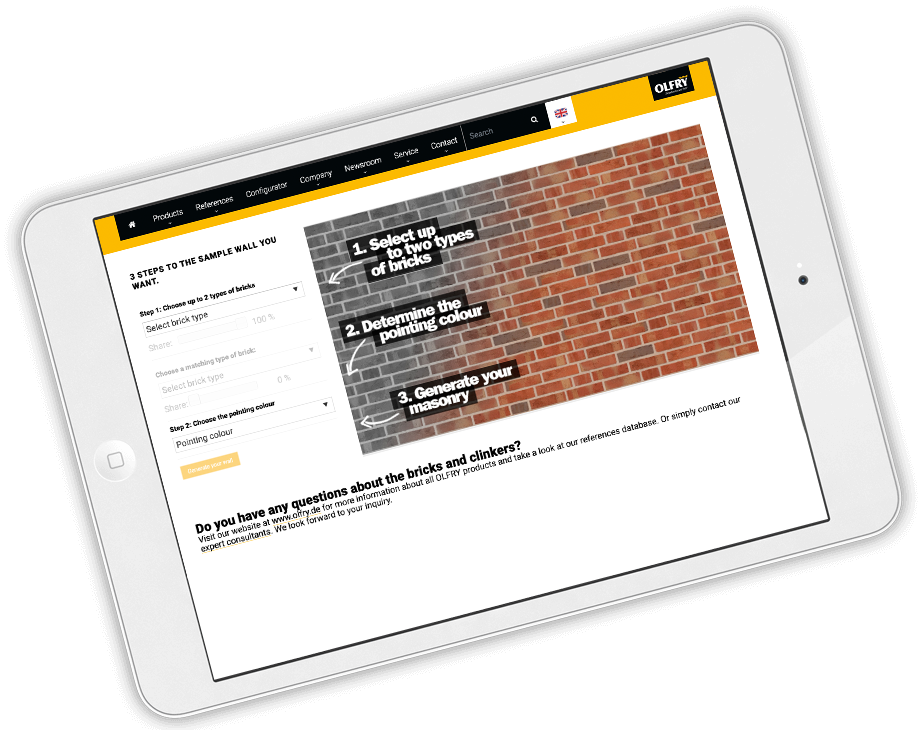

Our masonry designer

Create your own textures easily with our masonry designer. You can combine our clinker bricks with different mortar colours at the click of a mouse. The combination of two different clinker bricks is also possible.

The result can be saved for further processing as a high-resolution JPG file suitable for architects’ planning software.

Processing instructions

The production of permanently beautiful brickwork does not present any difficulties if the following instructions are observed during execution:

1. The total number of facing bricks and clinker bricks required for the respective building project must be ordered as a single order wherever possible and called up in good time before processing.

2. The facing bricks and clinker bricks are delivered to the construction site on pallets packed in plastic wrapping and set down by crane. They must be stored off the floor and protected against weather influences and dirt.

3. Most errors that can lead to damage are made during processing. For example, you should remove the facing bricks and clinker bricks from several packages at the same time in order to achieve a harmonious play of colours. If there is a risk of frost, stop working and do not use antifreeze.

4. Use a masonry mortar that matches the absorbency behaviour of the brick.

Facing bricks and clinkers:

Mortars of mortar group IIa with the following mixing ratio in parts (P):

1 P cement

1 P hydrated lime

6 P sand (grain size 0–3 mm)

The mortar consistency must be adapted to the low absorption capacity. Masonry mortars that are too stiff are not permitted. The clinker bricks should not be wetted because the water would form a disruptive separating layer which would prevent the mortar from being absorbed.

When using absorbent facing bricks, premature and excessive removal of water from the mortar by pre-wetting the bricks must be limited. When using ready-mixed dry mortars with improved water retention, pre-wetting of the bricks is no longer required.

A prerequisite for smoothing the joints is that the mortar has good formability. Instead of the construction site mortar described above, there are ready-mixed mortars available that facilitate processing. For smooth joints, ensure that the masonry is solidly filled and does not need to be improved later when smoothing the joints. When bricking up protruding mortar, brush off the excess with a trowel and smooth the joint flush with the stone with a suitably thick jointing iron or hose afterwards. The mortar must be removed immediately with a trowel to avoid contamination of the visible surfaces.

It is important that the mortar always has the same consistency when smoothing. A joint that is too fresh during smoothing becomes light. A joint that has been smoothed too late becomes dark. For this reason, always proceed from bottom to top. Use the same smoothing tool throughout the entire jointing process. After completion or if the work is interrupted, the masonry must be protected from soiling, soaking or rapid drying. If necessary, the brickwork can be washed off with a little water and suitable brushes during final cleaning to remove visible soiling. Chemical cleaning agents such as hydrochloric acid or cleaning agents containing acid must not be used.

5. Subsequent joining, which must be expressly agreed in the performance description, must be carried out with ready-mixed joint mortar that matches the facing bricks or clinkers.

The joints are to be scraped out evenly to a depth of 1.5 cm deep with clean edges. If the minimum scraping depth of 1.5 cm is not reached, the permanent adhesion of the joint mortar is not guaranteed. Scraping must be carried out before each work break while the mortar is still soft.

Cease all joining work if it is raining or very sunny. Rain can lead to leakage of the joint, sun to dry cracks, which promote moisture penetration damage to the masonry. With this in mind, you should protect the freshly joined masonry from moisture until the initial hardening.

6. The best and cheapest cleaning method is the careful bricklaying and avoidance of coarse soiling. To remove the final mortar residues, clean with water and a brush, spatula or scrubbing brush. Any splashes should be washed off with pure water before the mortar hardens. Do not use acids as cleaning agents. In case of heavy contamination, you should consult a specialist or the professional association of the brick and tile industry.

Vechta, June 2013

Links

This page provides you a selection of interesting links. If you would like to see your own homepage linked here, simply send us an e-mail with the address of the page and a short description. We will be happy to review your proposal and then get in touch with you promptly.

Zweischalige Wand Marketing e.V.

The working group Zweischalige Wand Marketing e.V. extols the product benefits of bricks on its very informative website. Its affiliated member companies – naturally including OLFRY – also present their maximum quality concepts in production and variety on these pages. Especially interesting for builders, architects and investors!

Downloads for building owners and constructors

What has made brick so unique as a building material for thousands of years? Why is the brick double-shell wall so popular with builders and architects? What construction techniques and designs are available for the bond and joints? Answers to these questions can be found in the architects’ folder with plenty of information to download.

Chamber of Crafts

The various Chambers of Crafts offer various Internet services on their homepage: Tradesman search, course search, apprenticeship exchange, expert search and company exchange.